KTI – SAUTER

KTI - SAUTER CombiMaster (CM)

The KTI - SAUTER CombiMaster is used when the fresh concrete has to be heated in winter before processing and cooled in summer.

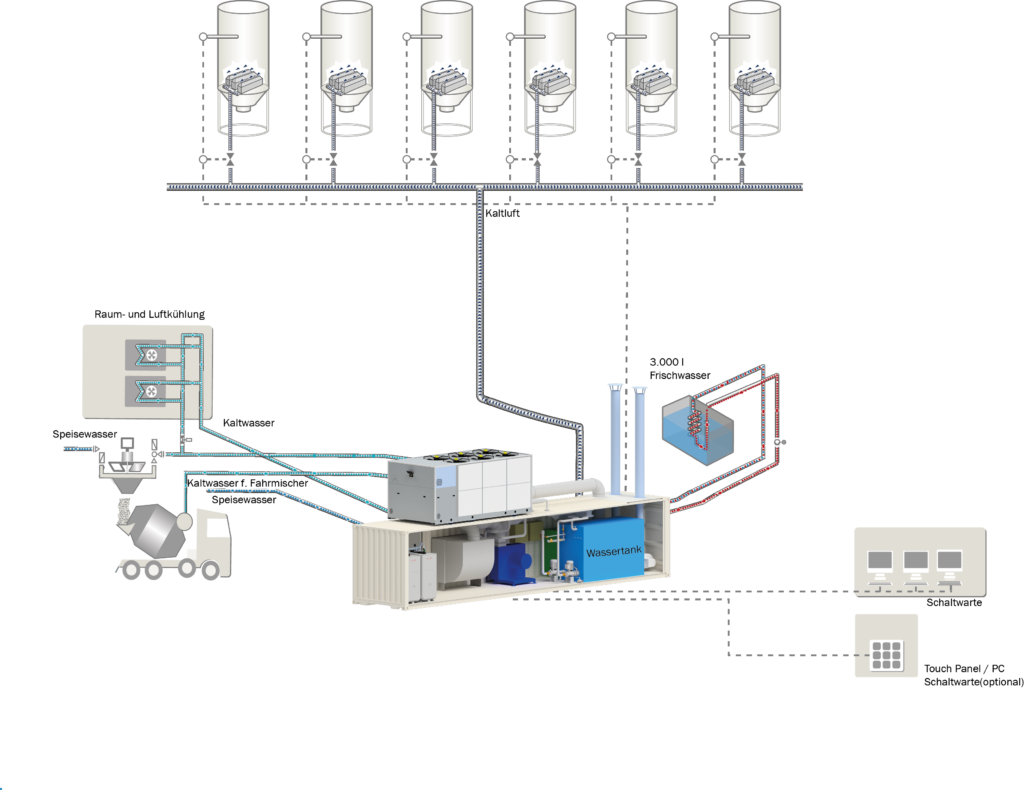

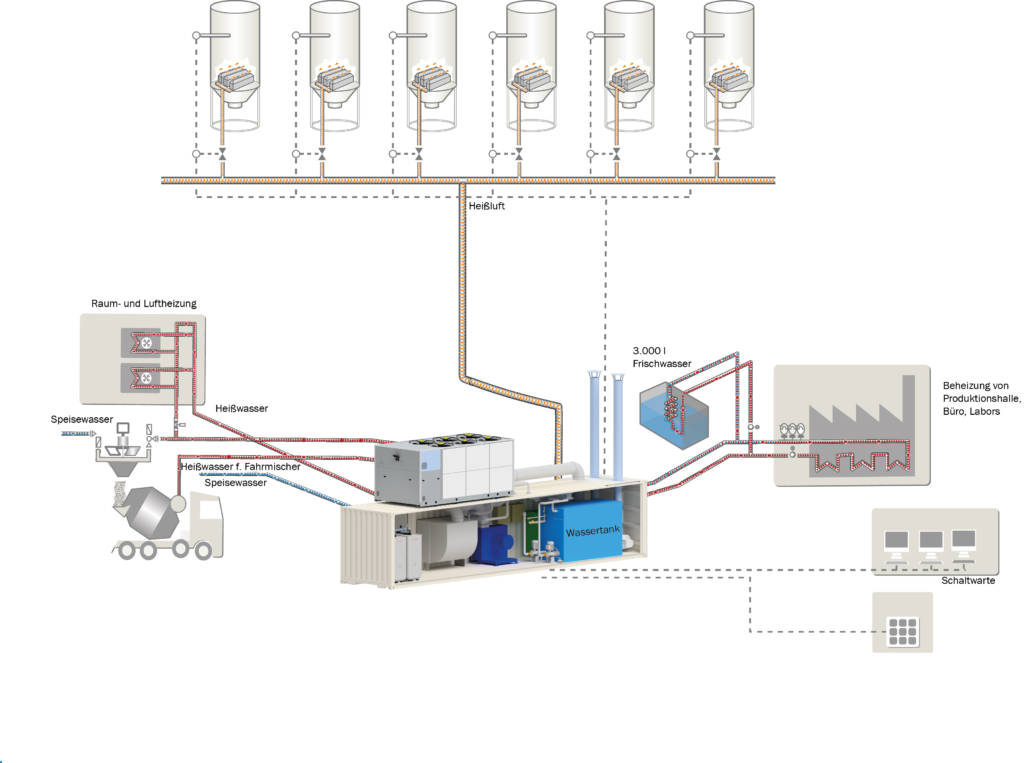

The CombiMaster contains a fully-fledged heating system and refrigeration system in one unit. This ensures the provision of feed water, which is cooled in summer and heated in winter. Likewise, cold air is generated in parallel in summer and hot air in winter for silo cooling or heating.

The CombiMaster is the only solution on the market that offers such versatile and flexible use.

The CombiMaster contains a fully-fledged heating system and refrigeration system in one unit. This ensures the provision of feed water, which is cooled in summer and heated in winter. Likewise, cold air is generated in parallel in summer and hot air in winter for silo cooling or heating.

The CombiMaster is the only solution on the market that offers such versatile and flexible use.

KTI - SAUTER CombiMaster (CM) in use at a ready-mix concrete plant, which can now produce winter and summer concrete thanks to the installation.

KTI - SAUTER CombiMaster (CM)

Plant information

KTI - SAUTER CombiMaster contains a complete refrigeration system for active cooling of water and air. Likewise this contains two heating units for heating water and air.

Heating and cooling, however, share the periphery. This has the unbeatable advantage that only one water pipe and one air pipe must be laid from the CombiMaster to the concrete batching plant. In addition, the CombiMaster is very compact, as the plants share one machine room.

Winter operation

In the winter, a KTI - SAUTER hot water system (HWS) heats the fresh water up to +85°C. A KTI - SAUTER hot air system (OLH) is responsible for heating the cold ambient air in order to heat the silos with the hot air. Both systems can be operated independently of each other, which is particularly useful in the transitional period. enormous savings brings with it.

Summer operation

In summer, a glycol chiller installed on the roof provides the required cooling capacity. The cold glycol is pumped through both a plate heat exchanger and an air register.

In the plate heat exchanger Fresh water cooledwhich is then buffered in the boiler of the hot water system.

In the air register, the ambient air is cooled before it flows into the silos. So unlike other products, the CombiMaster actually provides Cold air and not only ambient air is available for rock cooling.

KTI - SAUTER CombiMaster (CM)

The most important details at a glance

130

°C Hot air

85

°C Hot water

7

°C Cold air

4

°C Cold water

KTI - SAUTER CombiMaster (CM)

Your advantages of a KTI - SAUTER CombiMaster

- The KTI - SAUTER CombiMaster is a All-In-One System for heating and cooling.

- The KTI - SAUTER CombiMaster enables a trouble-free concrete production all year round.

- The KTI - SAUTER CombiMaster is highly mobile and very space saving due to the container construction.

- The KTI - SAUTER CombiMaster Reduces capital expenditures.

KTI - SAUTER CombiMaster (CM)

Product details

| Winter operation | Summer operation | ||

|---|---|---|---|

| Heating capacity | 600 kW | Cooling capacity | 257 kW |

| Hot water quantity | 5 m³/h | Cold water quantity | 5 m³/h |

| Hot water temperature | 85 °C max. | Cold water temperature | 4 °C min. |

| Fresh water inlet temperature | 5 °C | Fresh water inlet temperature | 15 °C |

| Heating power via air | 300 kW | Cooling capacity via air | 177 kW |

| Hot air temperature | 130 °C | Cold air temperature | 7 °C |

| Ambient temperature min. | -10 C° | Ambient temperature max. | 35 °C |

KTI - SAUTER CombiMaster (CM)

Complementary products

KTI – SAUTER

We are here for you

Your contact to our experts

How would you like to be contacted?