- a ship that takes the ice to sea for fishing

- a truck or vehicle that transports ice onwards

- a concrete mixing plant

- Reactors that require ice for cooling

- Ice dosing equipment for packing fish with ice

- ...

KTI – Plersch

KTI Ice Conveyor Systems

In addition to the production of ice, transport and conveying is also of enormous importance to achieve the best performance with KTI ice plants. Because the behavior of ice changes with changing conditions such as ambient temperature, humidity or thickness of the ice shards, KTI offers the right equipment for transport and handling for each type of ice.

KTI Ice Conveyor Systems

Plant information

After the ice is removed from the ice storage, it is conveyed to the destination. This can be the following:

KTI Ice Conveyor Systems

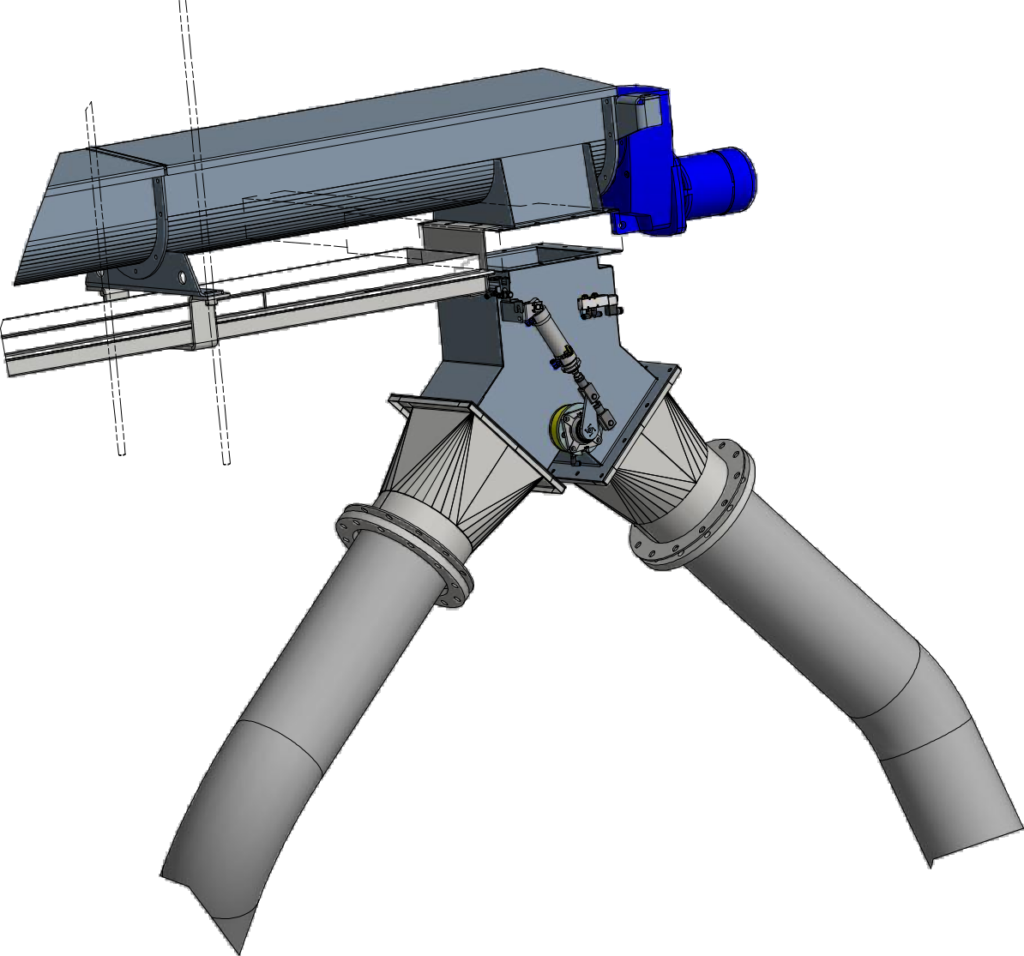

Transport with screw conveyors

A screw conveyor system is a economic and reliable solutionsg for ice transport.

Ice discharge

- The discharge screw is located directly under the ice storage (MIS) and is connected to an intermediate bunker that collects and buffers the ice for the immediate distribution.

- The discharge screw consists of a double trough system that allows the ice to pass through two outlets simultaneously to promote.

- Special versions even offer three outlets to which a blower system (BS) for pneumatic conveying can be connected.

- The ice can simultaneously be transported to two destinations if the ice storage is connected to two screw conveyors.

- For highest flexibility KTI offers a wide range of different diameters and lengths to cover all requirements.

- There can be several Screw conveyors be installed one after the other - so the ice can be conveyed to a remote loading point.

- All screw conveyors, for ice transport or ice discharge from the ice storage, are made of hot dipped galvanized steel manufactured. For special applications KTI also supplies screw conveyors made of Stainless steel or with plastic coating.

- The flat slide valves in the proven and reliable KTI design are a must for the correct handling From ice.

- The gate valves are mounted at the end of the screw conveyors and serve as a Separatorto keep the ice within a certain closed area.

- More importantly, they prevent warm and humid ambient air from entering and the screw conveyor is blocked by melted ice.

KTI Ice Conveyor Systems

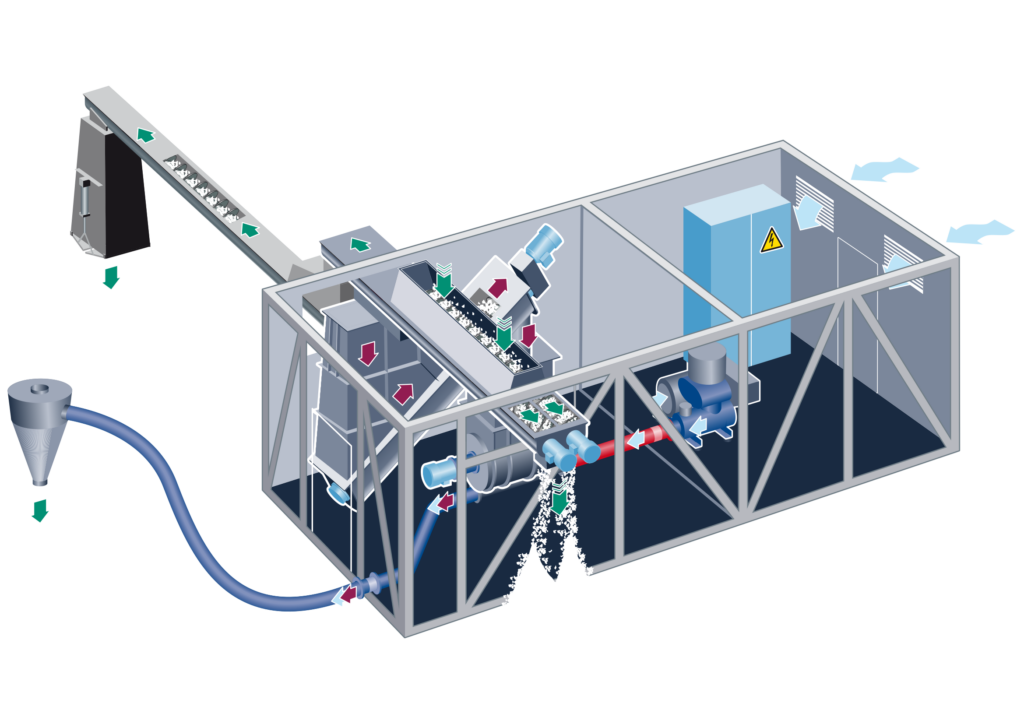

Pneumatic conveying

Pneumatic conveying is the most flexible solution for the transport of ice.

- On the one hand, the ice can be transported over long distances , and on the other hand the flexible conveying hose quickly moved to the destination. Therefore, the installation site of the ice plant plays a minor role.

- KTI's pneumatic ice conveying systems are installed directly in a container under the ice plant (up to 50 tons of ice capacity) or ice storage, or mounted in a separate steel frame, depending on the size and application.

- An essential component of a pneumatic ice conveying system is the Blower station (KTI Blower Station BS). This consists of the blower, a rotary valve for introducing the ice into the air stream, a screw conveyor for metering the ice and a fixed hose or fixed air ducts. The blower generates the required air flow and presses it through the rotary valve, which introduces the ice into the air flow in a metered manner.

- Blower stations are available in different sizes. The capacity is determined by the distance and the height difference. For example, at a distance of 200 m, a height difference of 15 m can be achieved.

- A Interconnection of several blowers makes it possible to supply several places where ice is needed at the same time.

KTI Ice conveyor systems

Your advantages of KTI ice conveyor systems

- KTI ice conveyors are economical and reliable solutions for the transport of ice.

- KTI ice conveyors transport ice easily, quickly and efficiently.

- Highly resilient raw materials ensure a long lifetime of the components.

- KTI Ice conveyor systems are usually used tailor-made produced for the customer's application.

- We advise you for the optimal conveying system for your ice.

KTI Ice Conveyor Systems

Complementary products

KTI – Plersch

We are here for you

Your contact to our experts

How would you like to be contacted?