Our solutions for the safe storage of temperature-sensitive substances

Our solution for the storage of substances for pharma & medicine

Ultra-low temperature cold storage (ULT)

The KTI Ultra Low Temperature (ULT) storage system is a high quality, flexible, mobile and reliable storage solution for vaccine manufacturers, pharmaceutical companies, logistics and distribution centers and research institutes. In the temperature range from -30°C to -110°C.

With air as the refrigerant, the ultra-low temperature storage system is the most innovative product on the market for storing vaccines, pharmaceuticals and other temperature-sensitive substances.

Your innovative, safe solution for storage at the right temperature

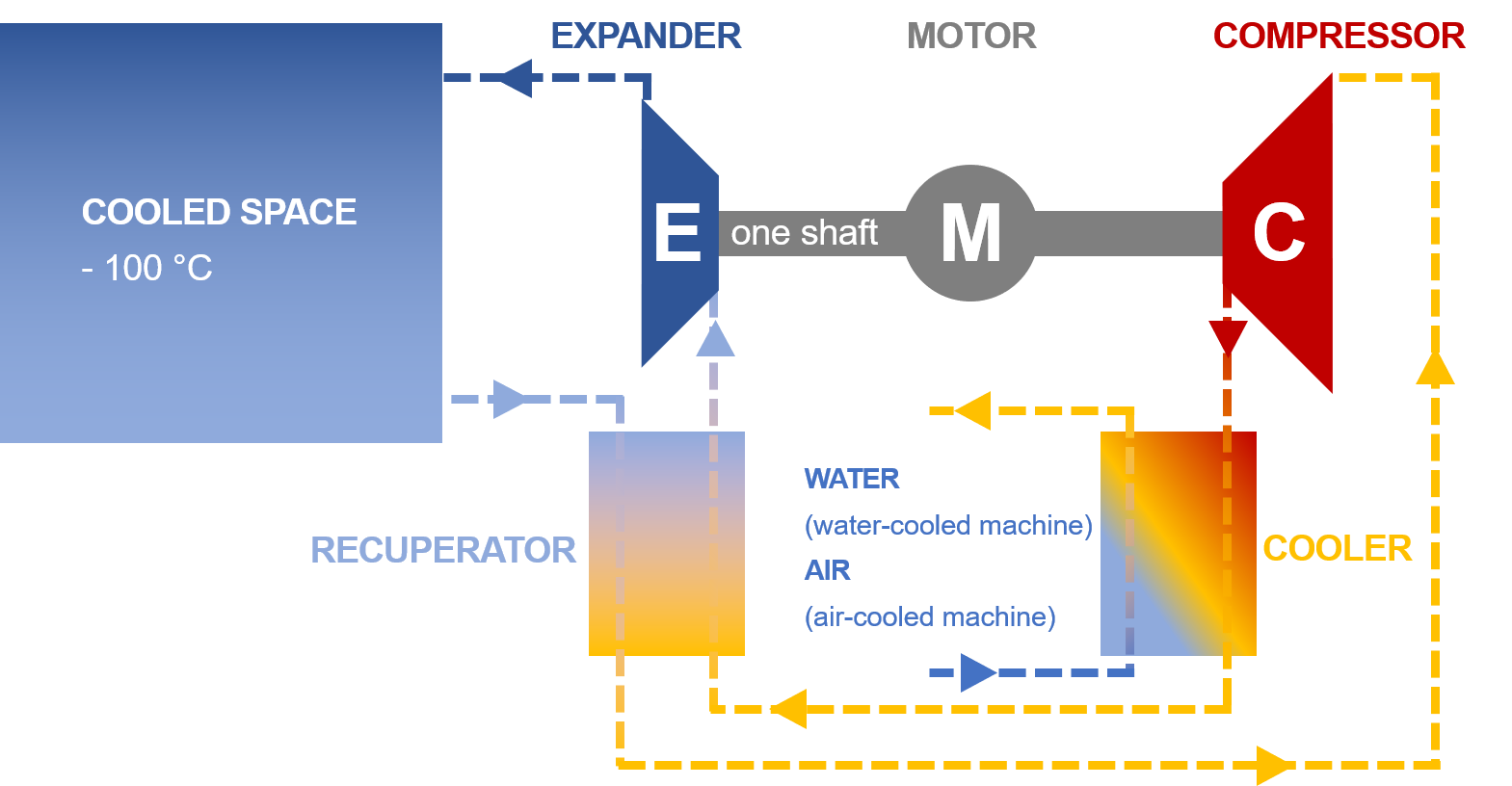

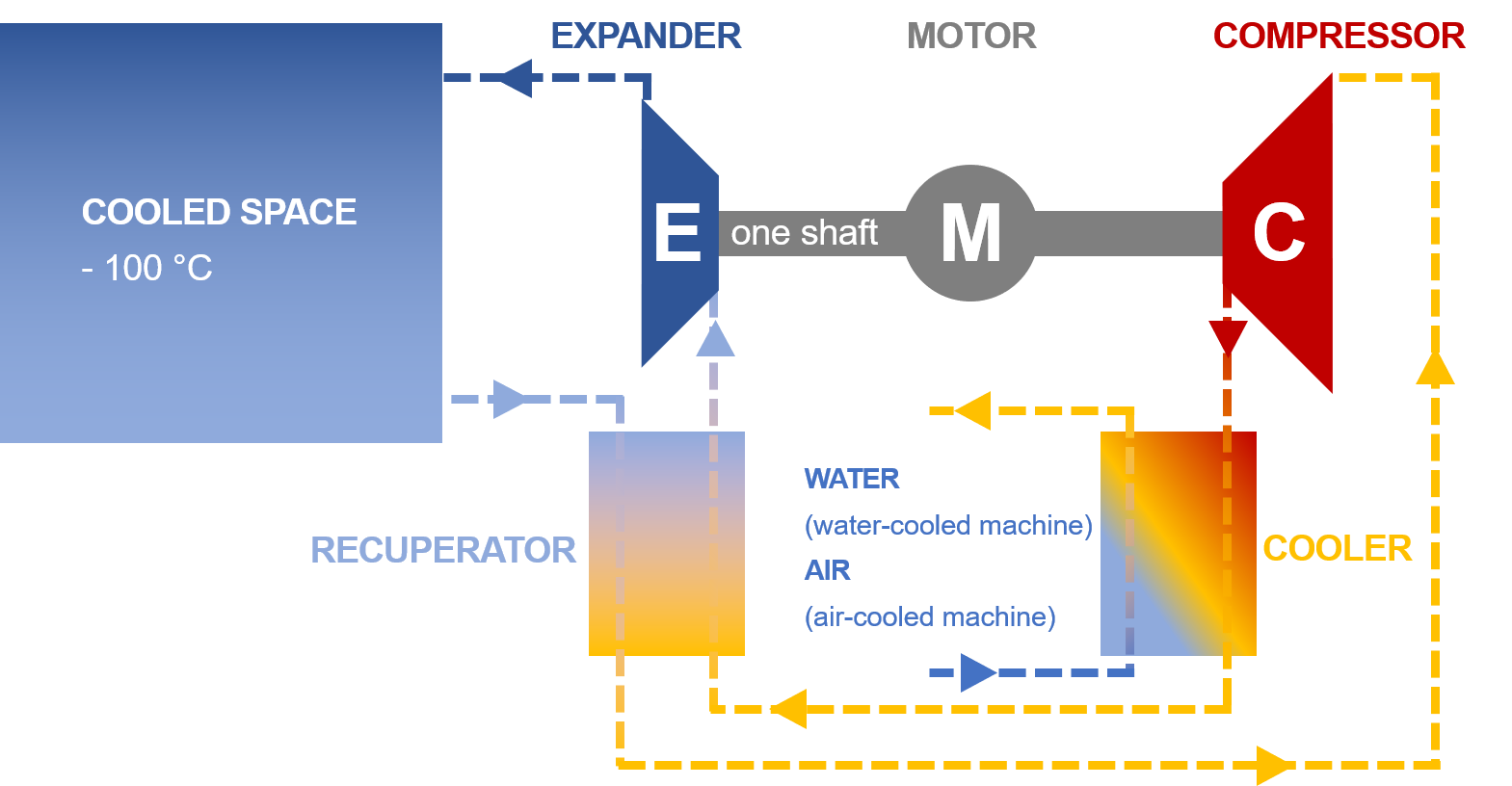

This is how the KTI air chiller works in our ultra-low temperature warehouse

Air as a natural refrigerant - pure sustainability

Highest operational reliability through innovation

One of the most common causes of refrigeration system failure is compressor damage. The reasons include liquid refrigerant entering the compressor or insufficient lubrication due to lack of oil or poor oil quality. In addition, in cascade systems for low-temperature plants, several compressors have to operate simultaneously, which increases the probability of failure.

Advantage of the KTI technology: Our technology has no phase change, no oil and is wear-free with its air bearing. This guarantees the highest level of reliability.

We are here for you

How would you like to be contacted?